Technology

PHYSICAL VAPOUR DEPOSITION (PVD) COATING

PVD (Physical Vapor Deposition) is a vacuum-based thin film coating process that transforms solid metal into vapor, then condenses it onto the surface of a product to create a hard, durable, and decorative or functional coating. Unlike traditional chemical-based coating systems, PVD is a dry, clean, and environmentally friendly process.

PVD coatings offer:

- Superior surface hardness

- Enhanced scratch and corrosion resistance

- Improved wear life

- Decorative color options with high adhesion

- Biocompatibility (for jewelry, medical, and wearable applications) This makes PVD ideal for high-end applications in jewelry, watches, electronics, automotive, tools, and precision parts where both aesthetics and performance matter. We offer two core PVD methods at Thailand Coating:

1. CATHODIC ARC PVD

Cathodic Arc PVD uses a high-energy electric arc to strike the target material (such as titanium, zirconium, or chromium). This arc vaporizes the metal into a plasma of highly energized ions, which are then deposited onto the product surface inside a vacuum chamber.

Key Benefits:

- Produces very dense and hard coatings

- Excellent adhesion and durability

- Ideal for applications exposed to high friction, wear, and impact

- Commonly used for: body jewelry, tools, automotive parts, hardware Considerations:

- May produce small “droplets” (micro-particles) in the film, which is acceptable for many industrial applications but not always for ultra-smooth decorative needs.

2. MAGNETRON SPUTTERING PVD

Key Benefits:

- Smoother coatings, ideal for high-end decorative or optical parts

- Greater control over thickness and uniformity

- Lower temperature process—safer for heat-sensitive substrates

- Perfect for electronics, watches, cosmetics packaging, and premium jewelry

Considerations:

- Slightly slower deposition rate compared to Cathodic Arc, but higher precision

Electroplating

- Decorative and functional electroplating

- Multi-layer systems for durability and adhesion

- Custom finishes for different industry standards

Automated Ultrasonic Cleaning Line

Preparation is key to quality coatings. Our automated ultrasonic cleaning line ensures that every item is perfectly clean before coating. It removes:

- Surface oils

- Oxides and residues

- Microscopic contaminants

Using a series of eco-friendly detergents, ultrasonic agitation, and DI water rinses, our cleaning line ensures optimal adhesion and consistent coating quality every time.

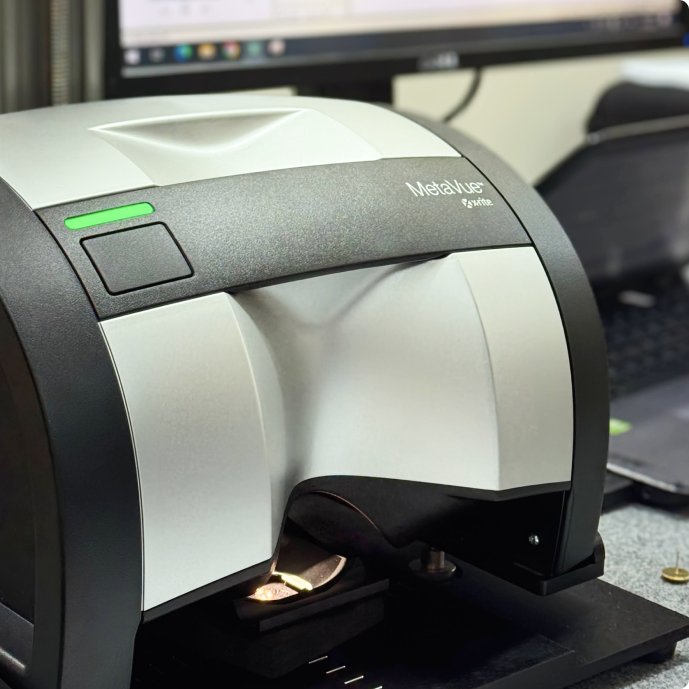

Quality Testing & Control

We use precise tools and industry protocols to ensure all coatings meet the required standards: Color Meter & Spectrophotometer We use color measurement devices to monitor tone accuracy, consistency, and color deviation (ΔE) against the desired reference. This ensures that every coated batch meets your brand’s visual specifications. Thickness & Adhesion Tests Regular destructive and non-destructive tests confirm coating thickness, durability, and adhesion. This is critical for parts exposed to wear or harsh environments. Salt Spray & Corrosion Testing (upon request) We offer optional corrosion testing to simulate long-term exposure and validate coating performance for harsh or humid environments.